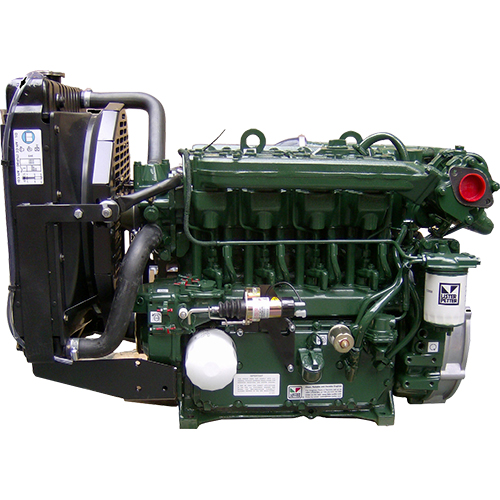

37.5 kW at 3000RPM, Lister Petter Alpha Series Diesel Irrigation Engine – Water Cooled

Model No.: LPWT4-01-IRRI

Lister Petter water cooled diesel engines are designed with Lister’s legendary performance and reliability. This Alpha series engine is perfect for irrigation and pumping applications. All diesel engines that are sold through Welling and Crossley are stringently tested to ensure quality in their products.

Power Rating: 37.5 kW

Engine Model: LISTER PETTER LPWT4

Engine Speed: 3000 RPM

Starter Voltage: 12V

Cylinder No.: 4

Aspiration: Turbocharged

Starting System: Electric

Approx. Fuel Consumption @ Full Load: 10.6 L/hr

Fuel Type: Diesel

Diam.: 786 x 480 x 574 (L x W x H)

Weight: 186 kg

Output Intermittent: 40.2kW, 53.9HP

Output Continuous: 37.5kW, 50.2HP

*Specifications are subject to change without notice

Irrigation Control Panel

The Irrigation Control Panel has been designed to meet the needs of most irrigation and pumping applications without being too technical. Its features were designed to accommodate the requirements of irrigation systems being used in stock watering or Block watering. For example, pumps filling turkey nest tanks around the farm which then gravity feed into watering troughs. Since then the control panel has been in many different applications equally as successful.

It features all the engine protection that is expected of a modern control panel monitoring Oil Pressure, Engine cooling temperature whether the engine is air or water, battery charge voltage and over speed. With a built digital tachometer with two separate odometers which are resettable to monitor service intervals or making fuel economy checks.

The control panel is also configured to read a pressure transducer which is supplied where required that can monitor the water pressure in the delivery line of a pump adding another level of protection to the system. If the pressure exceeds or drops below operator defined levels the controller will stop the engine to protect pipeline and pump.

The Irrigation Control Panel has three different methods which can be used to start the engine:

- Manual Start – Push the manual button then the Start Button.

- Auto Timed – In Auto mode a start and run time can be programmed to start daily or use 16 different start event times.

- Two wire start – close a no voltage two wire circuit to start the engine.

This panel can also accommodate various switches and controllers such as Flow Switches, Vacuum Switch gauges, and pre heaters.

Additional information

| Application | |

|---|---|

| Engine | |

| Power Rating (kW) | |

| Cooling |